What types of display can be bonded?

When it comes to Optical Bonding, it is critical that both the front surface of the LDC and the rear surface of the filter are flat. That being said however, the majority of displays can be bonded. At FORTEC UK, we undertake a test that determines the adhesion angle of each material layer.

What are the different methods of Optical Bonding?

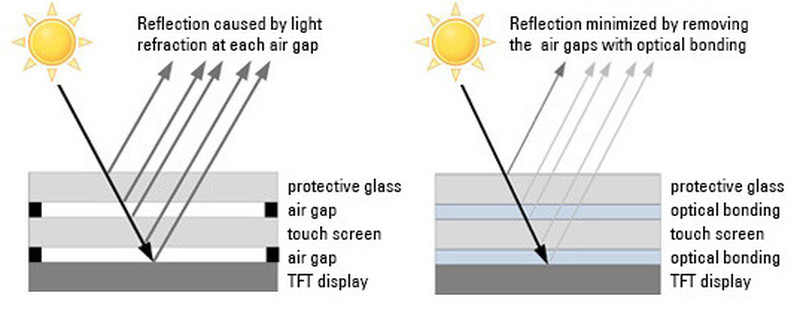

There are two different methods of Optical Bonding, the first being the more traditional. LOCA (Liquid Optically Clear Adhesive) or ‘wet bonding’ has long pioneered the process; however it is not without its problems. The only chance for rework is prior to the curing process and curing can be lengthy and time-consuming, also it is a labour-intensive process due to the requirement to create a ‘dam’ for the wet silicone.

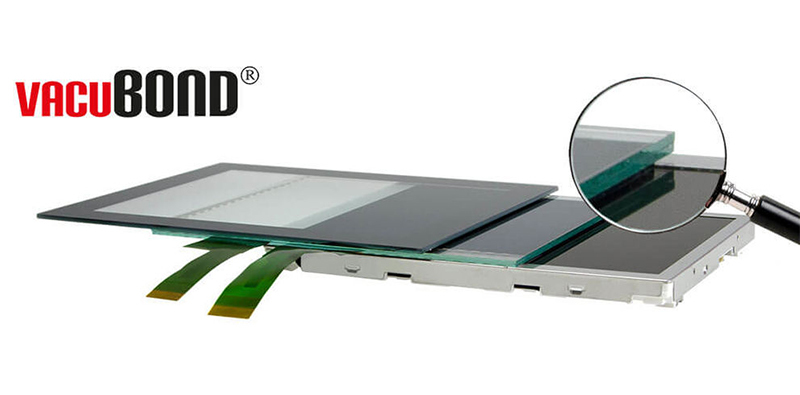

‘Dry bonding’ is the second process which was developed as a result of the high volume, high consistency requirements of tablet and smart phone bonding. This process refers to the vacuum application of a silicone sheet between the layers, which allows for multiple displays to be bonded quickly and simultaneously via a multi cavity Jig.

Which industries are most suited to Optical Bonding?

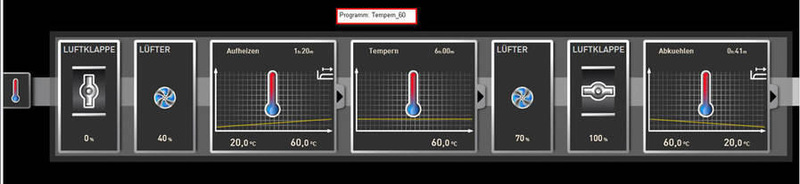

Optical Bonding lends itself perfectly to a range of different industries, typically those that require higher performing displays. Optical Bonding is suited to industries that tend to use rugged displays in high reliability environments or industries where displays need to be seen in high ambient light conditions. The process of Optical Bonding is particularly well suited and much more effective when applied to devices that operate outdoors or in heavily lighted environments.

Typically, Optical Bonding is used in and popular among the military, marine, medical, transportation and retail sectors.

Can the process of Optical Bonding be reversed?

Dry bonding can absoloutely be reversed. As there is no curing requirement for the VacuBond process, therefore dry bonding can be reversed throughout the life of the product, unlike traditional wet bonding.