Explore

- Products

TFT Display Modules

- Standard TFT Display Components

- High Bright TFTs

- High Resolution TFTs

- Stretch TFTs

- FHD Panels

- 4K UHD Panels

- Touch Display Panels

- Compact Panels

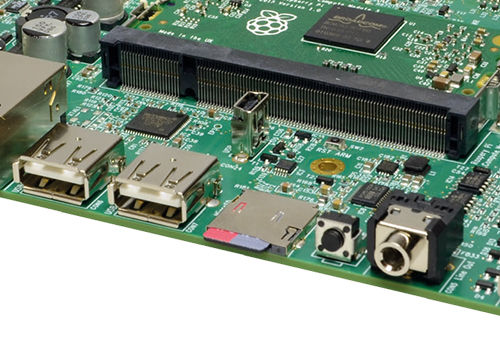

- IoT Compact Panels

- Transflective Panels

- Transparent Panels

- EMI Shielded TFT Displays

- Services

- Market Sectors

- Case Studies

- Demonstrations